Cutting-edge technologies combined: Drone Harmonys Automated Data Acquisition & Twinsitys digital inspection platform Twinspect

GeoZICHT allows bridge inspections to be completed in less time and far more accurate

21. Juni 2022

Feature in focus: Twinsity’s streamlined integration with all leading photogrammetry engines

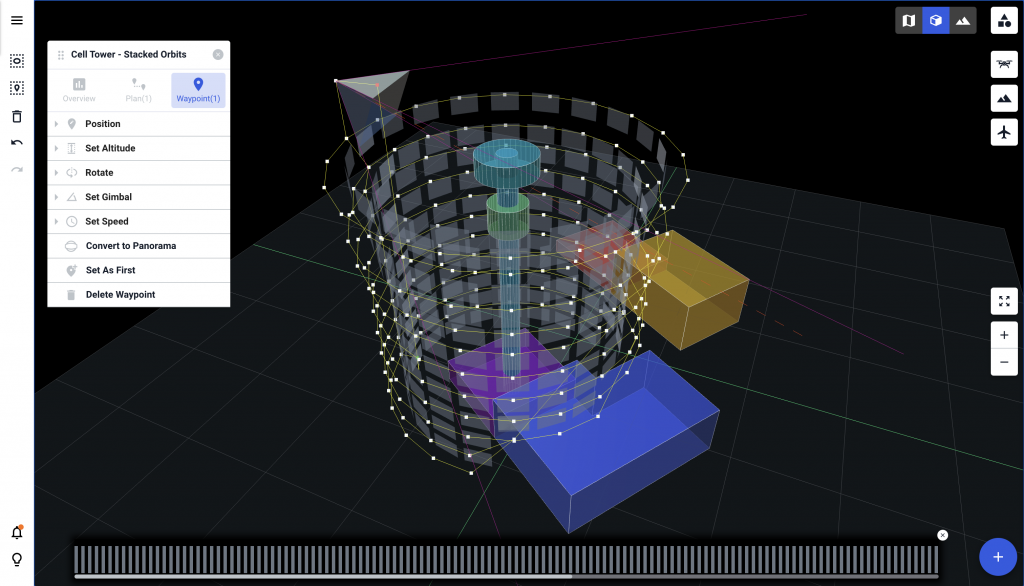

29. November 2022Automatically flying and capturing data off an asset – instead of manually. That sounds like substantial safety and cost benefits, and that’s exactly what the Swiss company Drone Harmony offers to its customers across a wide range of industries. Drone Harmony enables automated flight planning for drones, making data acquisition significantly safer and more accurate, as well as leading to better quality of collected data. The data acquisition workflow automation software assists with flight plan creation, plan visualization and flight execution. In this way, the detailed planning phase allows obstacles, difficult locations and parameters relevant to the inspection in question to be reliably included and considered in the planning stage. This enables the planning of a complex scene that includes much more than the object to be scanned. The platform allows to flexibly combine data from all relevant angles of even complex assets. For instance, nadir scans of an asset in question can be captured from above with the camera looking down and supplemented by several perimeter scans that capture the structure from the side. This way, a complex image of the object is created to gain the best possible insights into its condition. This automation of drone flights for data collection is a huge step forward for the drone industry and, in addition to cost and time savings as well as safety aspects, offers the further advantage that in recurring inspection processes the same asset can be captured over time by exactly the same flight paths, and thus optimally compared.

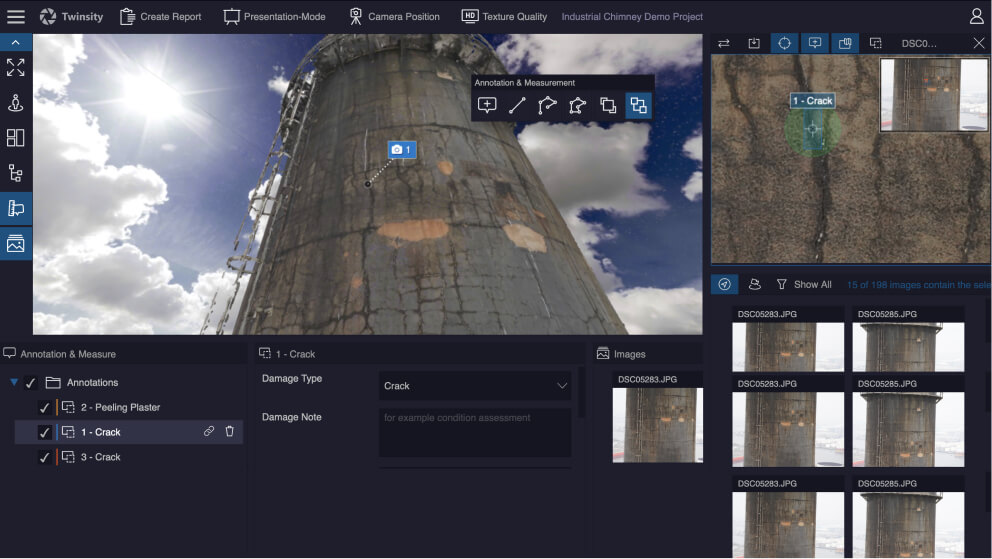

This state-of-the-art technology for the use of drones generates vast amounts of high-resolution data, which must subsequently be processed and made available in a useful manner. With the Twinspect digital inspection platform, the 3D model obtained from the data via photogrammetry software can be used efficiently together with the original images. The two resources are linked with each other in a technically precise way so that damaged areas can be reliably identified and inspected from multiple perspectives. With the help of the intelligent image database, the generated data no longer needs to be processed and reviewed manually; instead, the software automatically selects all relevant images for the damaged area in question. The platform brings all stakeholders of the inspection together in one place, allowing communication, inspection and collaborative work to be streamlined significantly. Inspection teams can gain valuable insights into assets and use a variety of tools to mark damage, take measurements, and create detailed automatically generated damage reports. This unlocks the data to its full potential and allows teams to add the most value to their workflow.

By automating and digitizing the inspection process through cutting-edge solutions such as automated drone flight planning and digital inspection platforms, technological advancements in the AEC industry continue to drive long-term changes in the how we look at infrastructure and assets and improve workflows.