Digital Bridge Inspection: The Role of Digital Twins and Technological Advancements

EIC ACCELERATOR PROGRAMME: €2.5 MILLION GRANT FOR TWINSITY

5. Juli 2023

Twinspect 2024.6.0 Release Notes

21. Mai 2024In our modern world, bridges serve as vital components of our transportation infrastructure, ensuring connectivity and safety for travelers. However, traditional inspection methods have often been cumbersome, time-consuming, and prone to danger. In response, engineers are increasingly turning to digital solutions to enhance bridge inspection processes.

Challenges of Traditional Inspection Methods

Traditional bridge inspections have long been reliant on manual methods, which come with inherent challenges. From safety risks associated with accessing hard-to-reach areas to the high costs and time required for thorough inspections, the limitations of traditional approaches have become apparent. Moreover, the reliance on physical inspections often results in incomplete data collection and the potential for oversight of critical structural issues.

The Role of Digital Twins and Technological Advancements

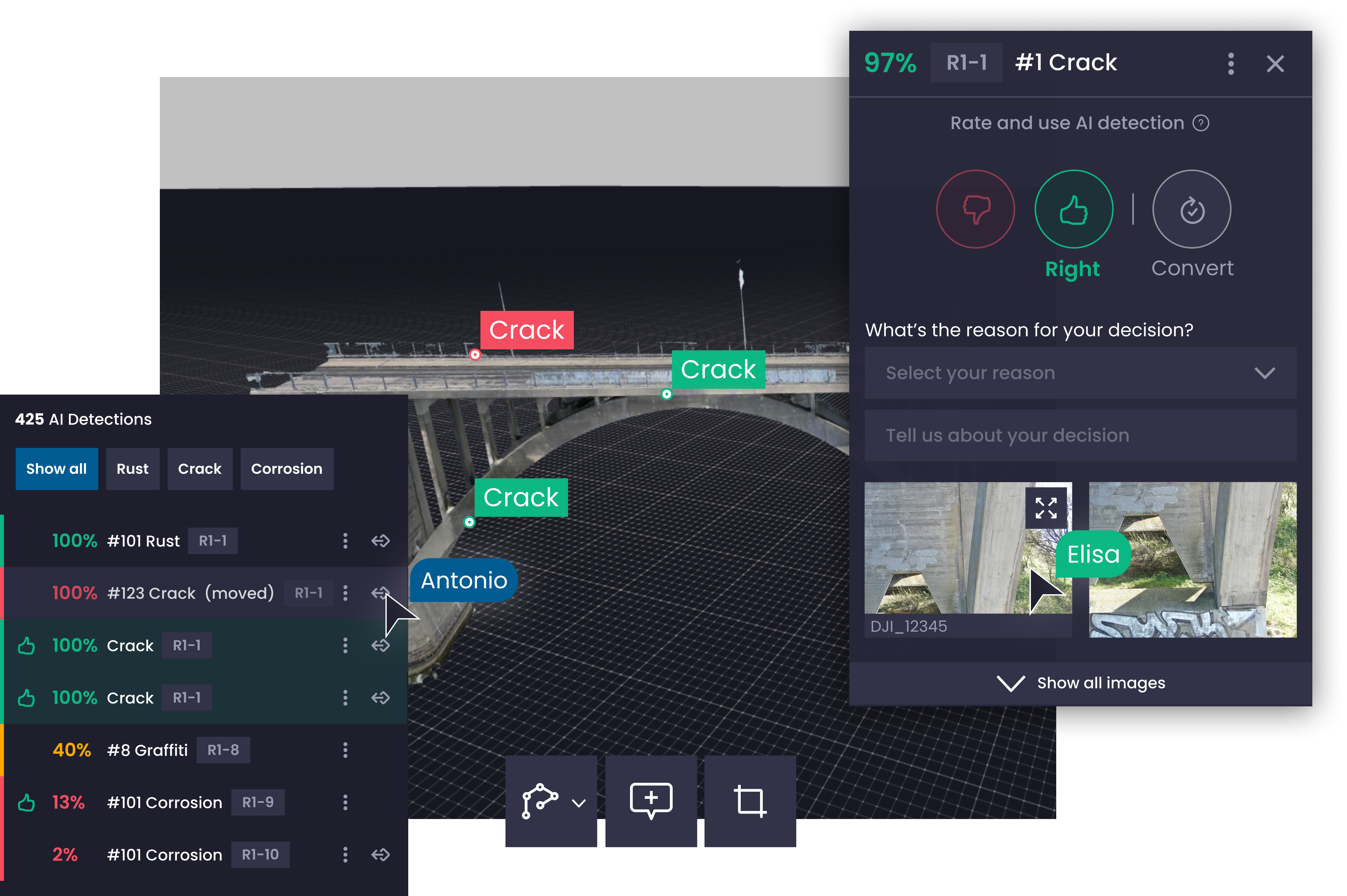

Digital twins, virtual replicas of physical assets, are at the forefront of revolutionizing bridge inspections. By leveraging digital twins alongside advancements in technology such as drone inspections, IoT devices, and artificial intelligence, engineers can now monitor bridge conditions with unprecedented accuracy and efficiency. Digital twins provide a comprehensive overview of bridge structures, enabling inspectors to detect anomalies, assess structural integrity, and plan maintenance activities more effectively.

Benefits of Digital Bridge Inspection

Digital twins, virtual replicas of physical assets, are at the forefront of revolutionizing bridge inspections. By leveraging digital twins alongside advancements in technology such as drone inspections, IoT devices, and artificial intelligence, engineers can now monitor bridge conditions with unprecedented accuracy and efficiency. Digital twins provide a comprehensive overview of bridge structures, enabling inspectors to detect anomalies, assess structural integrity, and plan maintenance activities more effectively.

The Future of Bridge Inspection

As digital technologies continue to evolve, the future of bridge inspection looks promising. With ongoing advancements in digital twins, IoT integration, and AI-driven analytics, inspectors will have access to even more sophisticated tools for monitoring and maintaining bridge infrastructure. This shift towards digital inspection methods represents a paradigm shift in the industry, paving the way for safer, more efficient, and sustainable bridge management practices. In conclusion, digital bridge inspection methods are poised to transform the way we monitor and maintain our critical infrastructure. By harnessing the power of digital twins and cutting-edge technologies, we can ensure the safety, reliability, and longevity of our bridges for generations to come.

Get in Contact with Twinsity